Popular Music

Columbia Records Manufacturing Process: 1946

The photographs that you see here were taken on a tour of the Bridgeport, CT Columbia Records factory in 1946. They provide a fascinating look at how music was reproduced in those days. The records we see being made, inspected, and shipped in these images are 10 inch discs that would have been played at a speed of 78 RPM. Today collectors refer to them by their speed - "78s" - but back then they were simply called records.

The photographs that you see here were taken on a tour of the Bridgeport, CT Columbia Records factory in 1946. They provide a fascinating look at how music was reproduced in those days. The records we see being made, inspected, and shipped in these images are 10 inch discs that would have been played at a speed of 78 RPM. Today collectors refer to them by their speed - "78s" - but back then they were simply called records.

1946 was approaching the end of one era of record production and the beginning of another. In two years — and in this very plant — Columbia would begin producing the first commercially viable Long-Playing, 33 1/3 RPM, 12 inch records (LPs). Unlike the typical one song per side limitation of 78s, a number of popular songs or a full movement of a classical piece could now be heard in one sitting, without interruption. In 1949, RCA Victor introduced the 7 inch 45 RPM single, and the format war was on.

Curiously, RCA Victor had already created a different version of the 33 1/3 RPM LP in 1930, but it failed to catch on with the public, in part because the Depression had inhibited consumer interest in new technologies. That early version of the LP was still commonly used for commercial purposes, especially as a means of recording radio programs for later broadcast.

Both the LP and the 45 were made of vinyl, unlike the 78s that we see here, which were made from shellac. Both materials have their pro and cons: vinyl records are flexible and capable of higher fidelity but the surface is easily marred by scratches or even direct sunlight, while records made from shellac are less prone to scratches but are comparatively heavy and brittle.

Technology in the recording studio was on the cusp of changing as well. Magnetic tape had yet to become the recording norm; instead, music was directly translated to the grooves of a lacquer or acetate record by a special needle that actually cut the grooves as the performance happened, hence the musical slang term for recording: "cutting sides."

The lacquer or acetate disc was then placed in the aptly named gold sputtering machine, an electroplating apparatus that would coat the lacquer with a very fine layer of gold, creating a negative, convex impression of the record’s grooves. Then thicker layers of nickel and copper were added to the disc in electroplating baths, and when the desired strength was achieved, the lacquer disc was carefully stripped away from the metal and the gold surface would be plated with nickel. That would become the master disc, also known as the matrix. From that disc a few so-called mother discs would be created, providing the molds for a large number of “stampers” that would be used to actually press the grooves into blank, pre-cut rounds of shellac. But even then the manufacturing process was far from complete, as these photographs will show.

The following images, as well as a few other interesting artifacts, are currently on display on the third floor of the Library for the Performing Arts at Lincoln Center.

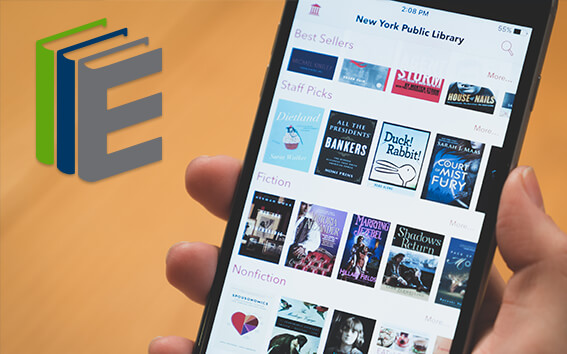

Read E-Books with SimplyE

With your library card, it's easier than ever to choose from more than 300,000 e-books on SimplyE, The New York Public Library's free e-reader app. Gain access to digital resources for all ages, including e-books, audiobooks, databases, and more.

With your library card, it's easier than ever to choose from more than 300,000 e-books on SimplyE, The New York Public Library's free e-reader app. Gain access to digital resources for all ages, including e-books, audiobooks, databases, and more.

If you don’t have an NYPL library card, New York State residents can apply for a digital card online or through SimplyE (available on the App Store or Google Play).

Need more help? Read our guide to using SimplyE.

Comments

Colimbia bridgeport

Submitted by Haiyai2u (not verified) on January 22, 2013 - 1:11am

United States Columbia Custom matrix numbering system 1933-1983

Submitted by Reginald Bartlette (not verified) on June 26, 2020 - 6:21pm

Photo of Engraving The Matrix

Submitted by John Swan (not verified) on September 16, 2014 - 9:45am

looking for information on a stamp block

Submitted by Richard (not verified) on September 16, 2015 - 10:49am

Looking for information

Submitted by Sandy Manzone (not verified) on January 29, 2016 - 12:26pm

Columbia Records factory in 1952

Submitted by Nick Sedelnik (not verified) on February 10, 2017 - 1:27pm

Ló vinil

Submitted by Galiotti ricardo (not verified) on May 5, 2021 - 11:03am